Hello everyone, I’ve been into flying wings since 2000 when I bought a Zagi online. As piloting style I can compare a flying wing to a snowboard ->> COOL. After abusing it greatly, I ended up mounting a couple of small Russian Norvel glow engines on it and eventually I had to bury it, since it became a pack of crumpled styrofoam. In 2005 I built another wing out of packaging tape and foam (see below).

I’ve been dreaming of a build-up flying wing for a while something like a Blended Wing Body covered in translucent film. I finally tried to make a very basic version with few curves and un-swept wings for simplicity.

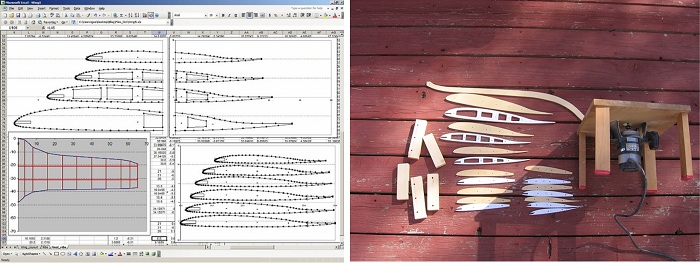

For airfoil design and moment calculation I use XFLR5 a very nice free aerodynamics software. I started with a high efficiency Eppler glider airfoil from UIUC database, reflexed it (raised the trailing edge to make it act like a positive momentum generating tail). I also thickened the leading edge (to make it collision proof) and refined it until I got a decent positive moment coefficient while keeping more than half of the gliding ratio of the original airfoil.

After finalizing the profile, I used Excel to draft it. I printed the ribs on a regular home printer. For the larger ribs near the base of the wing I had to splice the sheets of paper. I had some 1/8” and 1/16” plywood in the house as well as some carbon fiber rods from another project.

To the left is a screenshot of the Excel file and to the right there is a photo of my router (7$ from a garage sale) and the rib templates I made using a scroll saw and a 2″ sand drum monted in a drill press chuck. What you see on the top of the rib group (like an elongated letter “S”) is the template for the leading edge.

After gluing the ribs and the carbon spars the wing looked like the upper picture. Of course there was some wood work in the central area played by the ear.

The Excel file is not 100% detailed, it contains though the rib shapes and positions. The leading and trailing edge have also an element of improvisation. The pieces to the right of the upper picture are the two elevons and the lids to the radio bay and the servo link bay (close to the stubby tail). The bottom left picture is a detailed view of the central area (radio and servo bays) with the servo mechanisms mounted in.

In the lower right photo you can see the antenna as a red wire embedded into the left wing. I have few details to add but not until next spring. This plane is very strong but it will be fairly heavy (ready to fly at about 700 grams and 130 cm span) so I expect it to be quite fast. I used a British thermal-shrink cover type Ultralite.

Cheers,

George

Keith, No I have not finished it yet. My new job is very demanding. It will get easier though and next spring I should be flying. Unfortunately you cannot export it to the CAD package. Just get the idea and make everything from scratch in the CAD package. You will gain much more and get a better plane than this.

George, this is very impressive. Both what you are doing in Excel and the overall design you have created. I am fascinated with flying wings, especially those without sweep; flying planks. Have you completed yours? How does it fly?

I have just started playing around with your workbook. I have created a drawing of an airfoil. I wonder if I can export it to my CAD package?

I downloaded the excel sheet but there were no drawings like you have above

Ted, First this is one of my projects that I posted to show the drafting potential of excel. This was not made as an instructional, step-by-step post. You can surely build a wing with what is there but you need some experience and some improvisation. All this sheet has is the shape of the ribs, their position and spacing within the structure and the position of the spars (3 holes for circular carbon fiber). The rest, you need to improvise (leading/trailing edge, central section, elevons). I can make a post and upgrade the sheet (which I will probably do a little later) to the last detail but now I am too busy with other things. The workbook has 3 worksheets and the last one has what I exactly printed on my regular black and white home printer on standard paper. You can tinker with the parameters in the first worksheet if you want a different shape but what you see in the first photograph (the ribs in Excel) is there. What is missing is the leading edge and trailing edge info. I build the ribs, made the holes and notches, glued them on spars and after the glue (superglue) was dry I drew the shape of the leading edge on a plywood using the existing structure. Then I build a template and made 2 leading edges out of 1/4 regular plywood from Home Depot. I then glued them in maybe filing here and there in the ribs to adjust the joint with the leading better. I used segments of balsa on top and under the leading edge which after gluing them I had to sand with care. I forgot to mention that some of the ribs had their trailing edge bobed (to leave room for the elevons) and I did this in blocks (right and left block separatly). All the middle section was improvised AFTER the edges were glued. I used both balsa and 1/64 and 1/4 ply for the skid. I put the project on hold till next summer perhaps. George

Wow George!

That is quite simply the most amazing flying wing I have ever ever seen!

Its almost too beautiful to fly. I am a huge fan of the styrofoam models, but yours is way more classy. Congrats on an epic build!

Thanks, Patrick! It just takes muck longer to build and it’s heavier (the way I built it). Here in Colorado the air is 20% less dense at 7000 ft where I am located but fortunately we have stronger than average winds and plenty of slopes too. George